| PÁGINA PRINCIPAL |

| DIRECCIÓN |

| SERVICIOS |

| CURSOS PUBLICOS |

| REGISTRO |

| ARTICULOS |

| MAPA DEL SITIO |

| CONTACTO |

Course: Modeling and Optimization of Plastic Packaging Manufacturing Processes

Atlanta, GA, USA – May 15 - 17 2007 -- 3 days

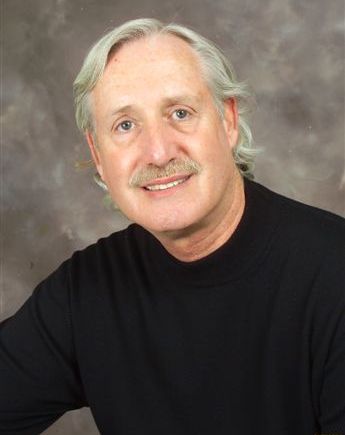

Instructor – Lawrence S. Mucha

Objectives – Develop a basis for the application of Designed Experiments (DOE) to the most common challenges in plastics molding processes including injection / extrusion / stretch and blow molding of PET , extrusion / blow for PE and PP – such as stress cracking, consistency of material distribution, top load resistance, dimensional consistency, visual defects and cycle and weight reduction.

Fees – US $1175 10 days in advance, US $1350 less than 10 days in advance; Discount for two or more participants from the same company = 15%; includes course materials.

Who Should Attend – General managers, technical managers, production managers, maintenance and quality personnel, process engineers.

What will the Participants Achieve – Understanding of how to address your processing issues, improve efficiencies and reduce scrap with scientific methods.

Themes –

- Workshop with process simulations to demonstrate the nature of plastics processing challenges

- Basic Statistics – distributions, parameters and statistics, differentiation between noise and real effects(the concept of statistical significance)

- How to design factorial DOE’s to optimize processes

- The design and analysis of DOE’s with Design Expert software

- Workshops with process simulations to practice the design and analysis of factorial DOE’s

- Introduction to scatter diagrams to relate material properties and product functionality

- The development of process simulations

- SOP’s for the design and optimization of and development of processes and products

PDF Course Description and Fax Registration Form

Instructor Bio: Lawrence S. Mucha